Slurry pump

Key words:

Slurry pump

Classification:

- Details

-

Product Overview

Slurry pump adopts excellent hydraulic model design, high efficiency and excellent performance. The pump body adopts the structure of pump shell + live lining wear-resistant materials, easy installation and maintenance, long service life. The technical conditions of the slurry pump comply with JB/T8096-2013 “centrifugal slurry pump” standard.

Product Features

Reasonable design of internal structure, not disturbed by the impact of slurry, no clogging, can be applied in a variety of working conditions.

Large diameter, low rate of wear-resistant and corrosion-resistant materials.

Interchangeable elastomer or metal liner, its good elasticity can play a role in absorbing and buffering the impact of the slurry.

Smooth operation, energy saving, low noise, low cost, high efficiency, easy maintenance, resistance to use and other advantages.

It can be applied in many kinds of working conditions.

Product Application

Conveying medium, concentrate and tailing slurry in mineral processing plants

Conveying ash in thermal power plants

Coal washing plant conveying medium

Conveying slurry in refineries

Working principle

Driven by the motor, before starting the slurry pump, the pump body and the suction line is filled with liquid. When the impeller rotates at high speed, the impeller drives the liquid between the blades to rotate together, due to the role of centrifugal force, the liquid from the center of the impeller is thrown to the outer edge of the impeller, and the kinetic energy is also increased. When the liquid enters the pump casing, due to the gradual expansion of the flow channel in the snail-shaped pump casing, the liquid flow rate is gradually reduced, a part of the kinetic energy into static pressure energy, so the liquid with a higher pressure along the discharge outlet. At the same time, the impeller center due to the liquid is thrown out of the formation of a certain vacuum, and the pressure at the impeller surface than the center of the impeller is higher, therefore, the suction line of liquid in the pressure difference into the pump. As the impeller keeps rotating, the liquid is sucked in and pressed out continuously.

Working conditions

Rotation speed: direct drive/pulley drive

1480/980/730/590r/min

Medium temperature: generally ≤ 80 ℃

Mass concentration of solid-liquid mixture: slurry concentration ≤ 65

Flow range: 40-3000m²/h

Lift range: 15-60m

More products

Vibrating Screen

-

YZS series circular vibrating screen

Mining vibrating screen structure: mainly consists of screen box, exciter, suspension (or support) device and electric motor.

-

Vibrating screens

Due to the strong vibration of the screen box, it reduces the phenomenon of material blocking the sieve holes, which makes the sieve have high screening efficiency and productivity. Simple structure, easy to dismantle and change the screen surface.

-

Horizontal screen

In the field of screening equipment, horizontal screen and inclined screen have their own characteristics, which are suitable for different screening scenarios.

-

Dewatering screen

The added value of dewatering screen: for products with low mud content, you can also use dewatering screen directly without using sand washing machine, which saves the customer's cost and can achieve the same effect.

-

Dewatering screen

It can be customized according to the output and moisture content, the body of the machine has a reinforcing plate on the side panels, the bottom is equipped with a support, the bottom is struck with a horizontal bar, the outlet is added with a triangular steel plate support, and the plate is thick.

-

Dewatering screen

Dewatering screen vibration motor, easy to replace, the base rubber spring is used to dampen the vibration, so that the amplitude is not too large, slow vibration, you can get off clean.

Cone Crusher

-

Wheeled sand washing machine

Adopting high-quality steel perforated screen mesh, durable, optimized mesh size, high cleanliness of sand washing.

-

Spiral stone washing machine

It is widely used for washing, grading and dewatering of small particles of sand and gravel in construction sites, sand and gravel factories, hydroelectric power stations, glass factories and other units.

-

Spiral stone washing machine

It is widely used for washing, grading and dewatering of small particles of sand and gravel in construction sites, sand and gravel factories, hydroelectric power stations, glass factories and other units.

-

Spiral stone washing machine

It is widely used for washing, grading and dewatering of small particles of sand and gravel in construction sites, sand and gravel factories, hydroelectric power stations, glass factories and other units.

Drum Sieve

-

Tumbler screen

Tumbler screen is a very widely used machinery in the sorting technology, is through the particle size of the particles to control the waste sorting, sorting high precision.

-

Tumbler screen

Tumbler screen is a very widely used machinery in the sorting technology, is through the particle size of the particles to control the waste sorting, sorting high precision.

-

Tumbler screen

Tumbler screen is a very widely used machinery in the sorting technology, is through the particle size of the particles to control the waste sorting, sorting high precision.

Cyclone

-

Cyclone set

Cyclone for personalized structural design products, according to the nature of the material, working conditions, the choice of different structures, different wear-resistant materials.

-

Polyurethane cyclone

Cyclone for personalized structural design products, according to the nature of the material, working conditions, the choice of different structures, different wear-resistant materials.

-

Ceramic cyclone

Cyclone for personalized structure design products, according to the nature of the material, working conditions, the choice of different structures, different wear-resistant materials.

-

Rubber cyclone

FX hydrocyclone specifications from Φ10-Φ840(mm), separation size from 2μm-350μm, to achieve large-scale and serialization.

Slurry Pump

-

Slurry pump

Reasonable design of internal structure, not disturbed by the impact of slurry, no clogging, can be applied in a variety of working conditions.

-

Slurry pump

Reasonable design of internal structure, not disturbed by the impact of the slurry, no clogging, can be applied in a variety of working conditions; large diameter, low rate of wear-resistant and corrosion-resistant materials.

Sieve Net

-

Welded screen

Welded screen mesh is made of high quality welded wire welded with high temperature quenching and low temperature tempering, which has super wear-resistant, corrosion-resistant and oxidation-resistant service life is 3-5 times of ordinary screen mesh.

-

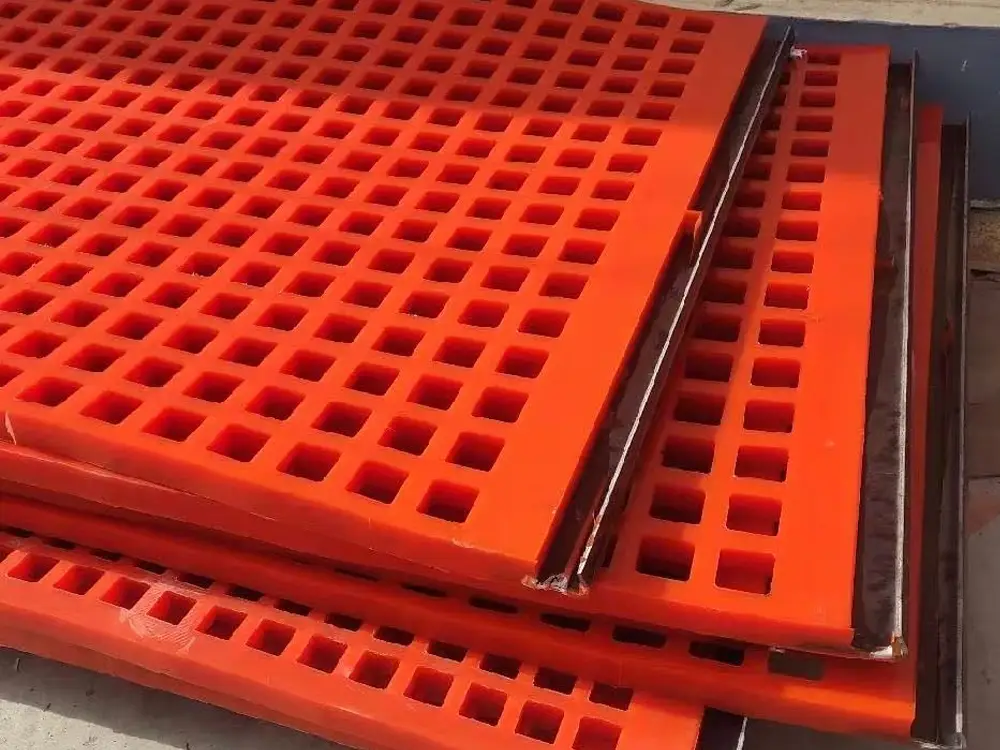

Polyurethane screen mesh

Polyurethane screen mesh is a high-performance screening material, made of polyurethane material with high elasticity, abrasion resistance and chemical corrosion resistance.

-

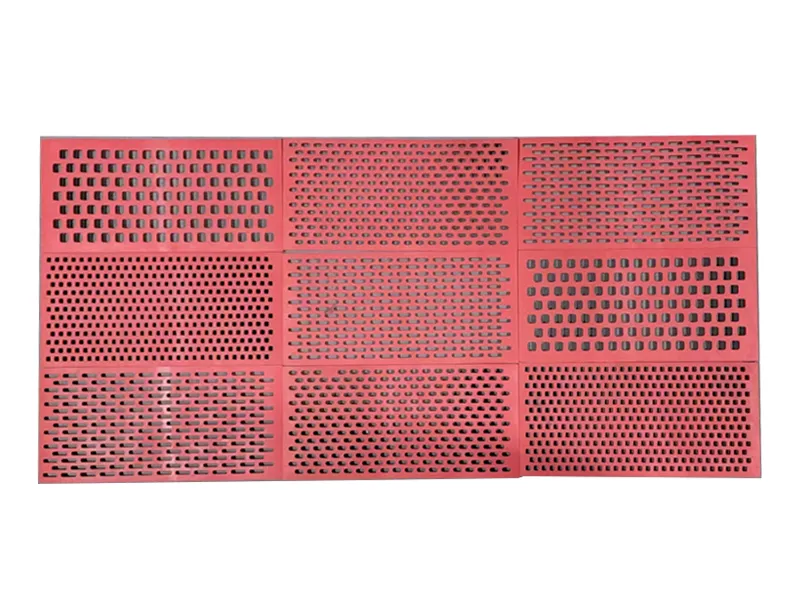

Punched mesh

Can be customized according to customer's drawings: high strength stamping, bending resistance, anti-aging, mesh surface is flat, smooth, sturdy and durable.

-

Bending perforated mesh

Product features: high-strength stamping, bending-resistant, anti-aging, mesh surface is flat, smooth, sturdy and durable. Perforated mesh is also called perforated plate, perforated screen, perforated sieve plate, hole plate and so on.

-

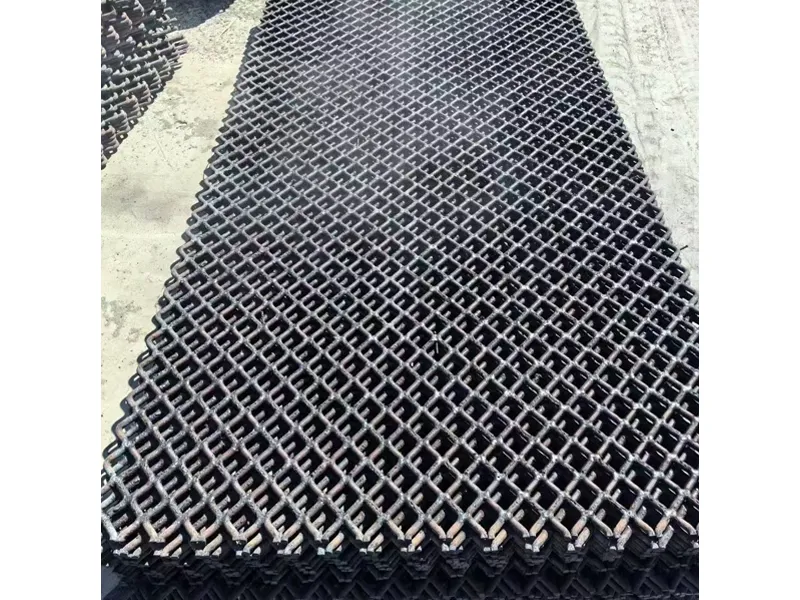

Manganese steel woven screen

65/82B manganese steel crimped wire mesh is also called mine screen crimped wire mesh, coiled vibrating screen. According to different materials can also be called iron crimped wire mesh, steel crimped wire mesh, stainless steel crimped wire mesh, coiled crimped wire mesh.

-

Plugging net

Anti-blocking mesh, also known as self-cleaning screen, screen bars are movable, eliminating the phenomenon of material blocking holes, the material is generally used heat treatment 65 manganese steel.

-

Rubber sieve mesh

Rubber screen is a kind of industrial filtration material made of rubber and other reinforcing materials, with excellent characteristics of wear resistance, corrosion resistance, anti-aging, etc. It can work stably for a long time under the harsh working environment.

-

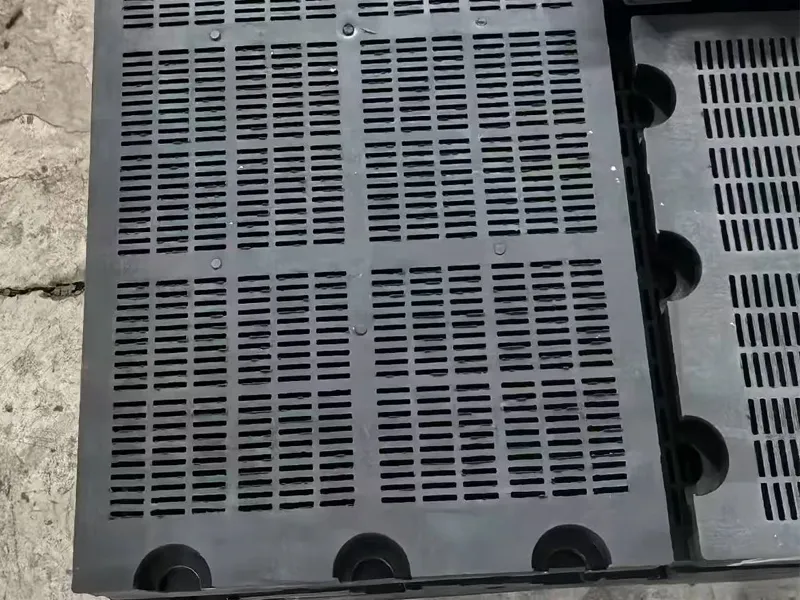

Polyurethane bar screen

Polyurethane bar screen is made of polyurethane wrapped steel wire rope drawn and bonded. The service life is slightly lower than that of ordinary polyurethane mining screen, but the output is greatly improved and even exceeds the service life of ordinary metal woven screen.

-

Stainless steel bar screen

Stainless steel slit screen is a metal mesh structural element used for screening and filtering, which is widely used in screening, filtering, dewatering, desludging and other operations in many industries.

-

High frequency sieve mesh

High-frequency screen is a kind of screening equipment that adopts high-frequency vibration screening principle, which has the advantages of high efficiency and low maintenance cost.

Wear-resistant Pipe

-

Ceramic lined wear-resistant pipes

Can be customized according to customer drawings: ceramic lined pipe is a kind of pipe using ceramic material as the liner, mainly used for the transportation of strong corrosive media.

-

Wear-resistant pipes

Good abrasion resistance, lining layer for wear-resistant ceramics, Mohs hardness up to 9.0, its wear-resistant life is ten or even dozens of times that of hardened steel.

-

Ceramic lined wear-resistant pipe

Can be customized according to customer drawings: ceramic lined pipe is a kind of pipe using ceramic material as the liner, mainly used for the transportation of strong corrosive media.

-

Polyurethane lined wear resistant pipe

Operation resistance is small, the inner surface is smooth, and never rust, the resistance coefficient of clear water is small, which can reduce the operation resistance and operation cost. Corrosion resistance, anti-scaling

-

Polyurethane lined wear resistant pipe

Ceramic lined pipe inside and outside the two layers of different properties of the material, the outer layer is steel pipe inner layer is high aluminum ceramic, wear resistance than carbon steel pipe 20 times higher.

Crushing Equipment

-

PF series impact crusher

It is used in metallurgy, mining, cement, chemical industry, refractory materials and ceramics and other industrial sectors, as well as highway construction, water conservancy engineering, building gravel, mechanism sand processing and other fields.

-

PEC series impact crusher

Adopting high-strength materials and advanced manufacturing process, it has the advantages of higher structural strength, higher reliability of equipment, larger crushing ratio, higher output and lower comprehensive processing cost.

-

PE series jaw crusher

PE series jaw crusher, commonly known as jawbreaker, is often used as primary crusher in various stone production lines and ore crushing production lines.